Marine Sewage Treatment Plant SM-P SERIES

Marine Pollution Prevention Equipment

SKMARINTEC CO., LTD. a leader in marine pollution prevention equipment pursuing BLUE OCEAN

3EASY SYSTEM

-

01

EASY INSTALLATION

An disassembly assembly method capable of quickly removing and installing old or defective products installed on existing ships

-

02

EASY OPERATION

Intuitive touchscreen OS adoptionEasy operation and management

-

03

EASY MAINTENANCE

Convenient maintenance with no sludge and no clogging of pipes with a patented Auto Back Flushing method

Marine Sewag Treatment Plant SM-P SERIES

Outline

- 1. Easy-to-use fully automatic SYSTEM

- 2. Faster electrolysis and high efficiency

- 3. economic feasibility

- 4. a powerful sterilizing effect

- 5. Convenient maintenance

- 6. Saving costs

Characteristics

- - Fully automatic operation without manual back flushing with digital control system by electronic control

- - Fast sewage treatment time (10 to 15 minutes/cycle) because electrochemical energy is supplied to sewage and oxidized

- - Size that is more than 1/2 smaller than Bio Type reduces fuel efficiency, can be installed in a small area, and does not require consumables

- - Satisfy IMO regulations further strengthened by the strong sterilization power of dental hydrochloric acid (Hocl), and remove N, P and removing N, P and odors

- - Knockdown design for convenient installation and maintenance

-

01

- Detachable Design

- - Convenient installation and maintenance

- Allows quickly replacement installation of existing ships

-

02

- Easy operation

- - Application of TFT LCD Controller with Touch Screen

-

03

- Easy maintenance

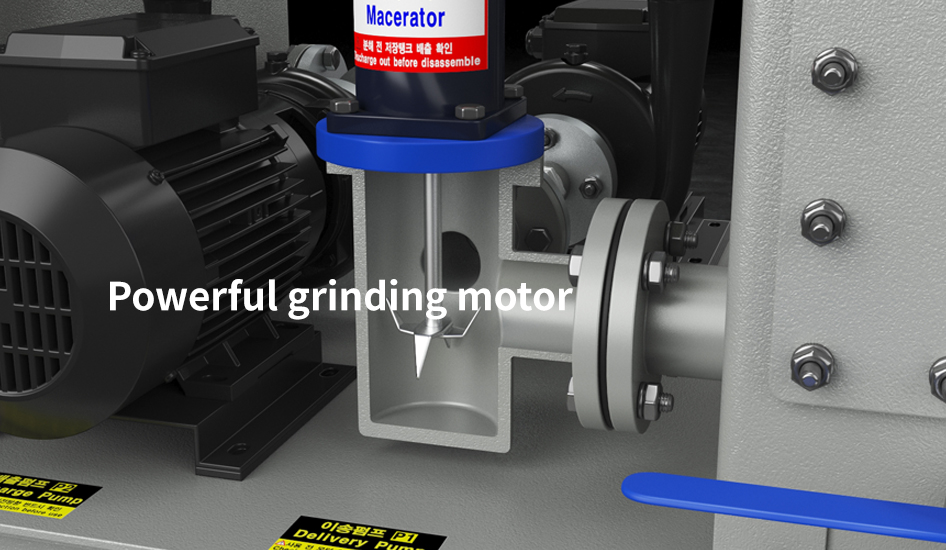

- - Powerful macerator motor free of sludge

- Automatic electrode cleaning ensures no clogging of pipes

- Seawater is electrolyzed and sterilized, and separate disinfectant is not required

Font View

Rear View

Advantages of SM-P Series

swipeLeft and right draggable

| Division | Existing product | SM-P Series | Disadvantages of existing products | Advantages of SM-P Series |

|---|---|---|---|---|

| Electrolysis Pipe parts | Plate type | Pipe type | The plate type made of P.E material is weak to heat and pressure, causing chronic water leakage problems (engine room odor). | Solve the problem of electrolysis (patent applied) leakage in pipes during transport without a separate electrolyzer. |

| Electrode cleaning | Periodic cleaning for 1~2 months |

Electrode automatic cleaning | Inconvenience in periodic cleaning of electrode plates. Fecal sludge deposited between narrow electrode plates causes performance degradation and breakdown. | Automatic cleaning of electrode pipes during each operation (no sludge formation) |

| Stability | General specifications | Explosion proof specifications | Hydrogen gas and methane gas generated during electrolysis require explosion-proof specifications for the level sensor inside the tank. | Low current control (I-Solation) circuit adopted explosion-proof detector from German NOLTA |

| Combination method | All-in-one | Separate type | Installation and repair work is inconvenient due to the electrolyte plate being exposed to the outside. | Small size and convenient knock-down method for quick and convenient installation and repair. Quick replacement for existing ships. |

| Working method | Analog | Digital mainboard | Impossible to check for malfunction Engine room interlocking control not possible |

Alarm function for abnormalities through program operation Linked control with engine room possible |

MEPC.227(64)Discharge limits

| MEPC.227(64) Discharge limits | |

|---|---|

| Description | MEPC.227(64) |

| Faecal-Thermotolerant Coliforms | 100/100 ml |

| Suspended Solids | 35mg/l |

| BOD5 | 25 mg/l |

| COD | 125 mg/l |

| Chlorine | 0.5 mg/l |

| T-N | 20 mg/l |

| T-P | 1.0 mg/l |

Specification

swipeLeft and right draggable

| Type | Number of Persons | Hydraulic Load [m3/d] | Organic Load [kg BOD5/d] | Length [mm] | Width [mm] | Height [mm] | Dry Weight [kg] | Wet Weight [kg] |

|---|---|---|---|---|---|---|---|---|

| SM-16P | 16 | 1.3 | 0.86 | 1,100 | 770 | 1,230 | 430 | 555 |

| SM-25P | 25 | 2.0 | 1.35 | 1,200 | 770 | 1,230 | 463 | 603 |

| SM-35P | 35 | 2.8 | 1.89 | 1,300 | 770 | 1,300 | 496 | 666 |

| SM-45P | 45 | 3.6 | 2.44 | 1,300 | 870 | 1,300 | 528 | 724 |

| SM-60P | 60 | 4.8 | 3.25 | 1,300 | 870 | 1,400 | 561 | 779 |

| SM-80P | 80 | 6.4 | 4.33 | 1,400 | 870 | 1,400 | 594 | 849 |

| SM-100P | 100 | 8 | 5.42 | 1,400 | 970 | 1,500 | 627 | 945 |

| SM-150P | 150 | 12 | 8.13 | 1,600 | 970 | 1,600 | 640 | 1,039 |

| SM-300P | 300 | 24 | 16.27 | 2,400 | 970 | 1,800 | 973 | 1,948 |

| SM-450P | 450 | 36 | 24.40 | 3,200 | 970 | 1,800 | 1,100 | 2,560 |

| POWER | 220V, 380V, 415V, 440V / 50Hz, 60Hz / 3Ø | |||||||